To many, rolling stock management and fleet management might seem the same. After all, we're talking about managing moving assets. Yet, beneath this surface-level similarity lies a world of distinct challenges and specialized focus areas.

Imagine, for a moment, the bustling rail networks across Britain. Every day, thousands of trains from high-speed intercity express to local commuter services whiz across the landscape. The sheer complexity of keeping these iron behemoths running isn't just about tracks and schedules. This is a colossal financial undertaking.

The maintenance and financing of Britain's mainline railway rolling stock alone is valued at a staggering £1.8 billion per year, accounting for roughly 15% of the total railway operating cost. Picture a passenger fleet of 12,000 vehicles across 64 different classes, with an average age of 17.3 years. And even as these veterans continue their service, new titans are always on the horizon. This process isn't just about managing vehicles; it's about orchestrating engineering, finance, and logistics simultaneously.

This article delves into the nuances of each, primarily focusing on rolling stock management, clarifying its definition, scope, and unique challenges. We'll add more stock to the strategy of managing rail vehicles versus a broader array of transportation assets. Understanding these distinctions is crucial for optimizing operations. See how we maximize the lifespan and utility of valuable assets in rail, a key transportation sector.

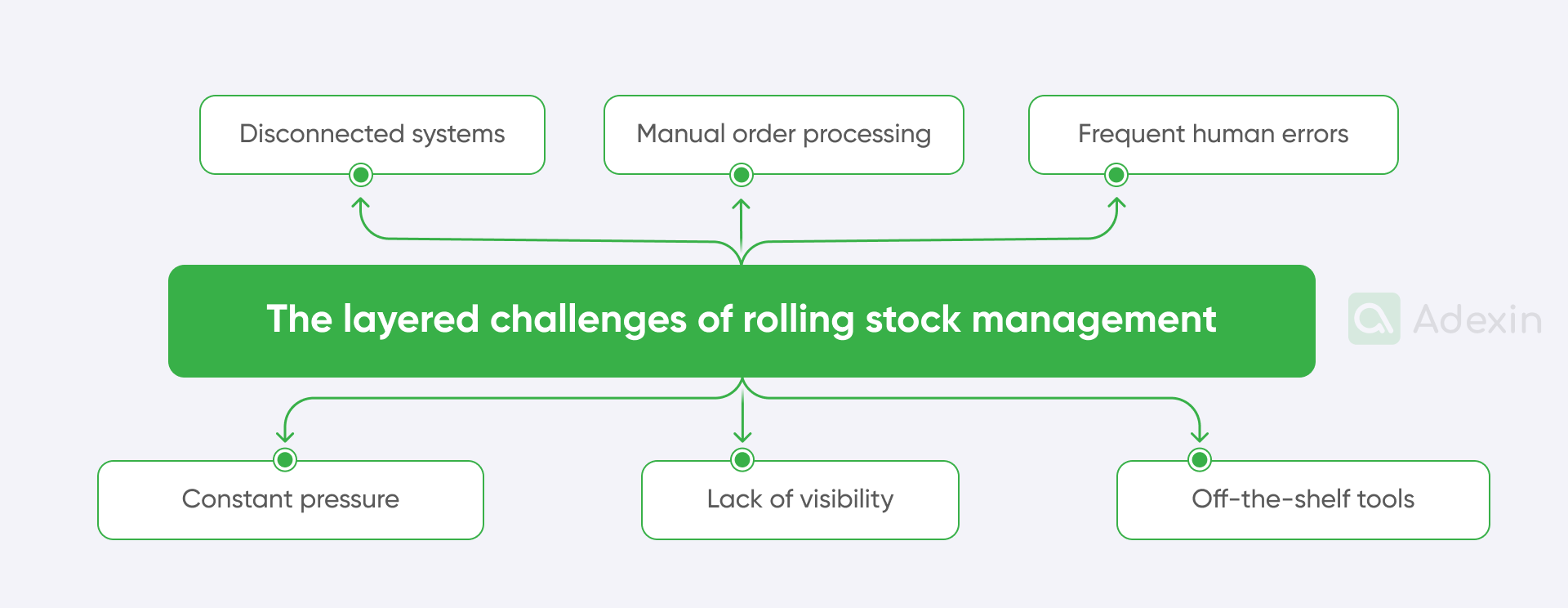

The layered challenges of rolling stock management

When we peer into the intricate world of rolling stock management, we often encounter challenges. These challenges, much like the life stages of rolling stock itself, from when it rolls off the production line to its eventual terminal decommissioning, present their unique risks and demand tailored approaches.

At the outermost layer, the complexities often stem from the vast ecosystem in which rolling stock operates. Think of it like a conductor trying to lead an orchestra where half the musicians are playing from different scores. What we frequently see:

Disconnected systems. Warehouse management systems (WMS), transportation management systems (TMS), enterprise resource planning (ERP), and rolling stock management systems all work in their own silos.

Manual counts, order processing, and slow workflows. This fragmentation means that instead of a seamless flow, you have inefficient processes, a critical risk during the "Infant Mortality" stage of a train's life, when design and manufacturing faults or interface issues are being ironed out.

Frequent human errors. The lack of smooth data flow also leads to costly mistakes that can echo through every stage of an asset's life, from those initial early-life operating faults to the mounting maintenance costs and lack of spares that plague a train in its ageing years.

Off-the-shelf tools. Often fail to address unique business needs, leaving crucial gaps in management capabilities that generic solutions simply can't fill. It's like trying to fit a square peg into a round hole.

On the internal layer, the challenges shift towards operational visibility and strategic foresight. Imagine trying to navigate dense fog, that's what it feels like.

Lack of visibility, leading to reactive management, becomes particularly problematic during a rolling stock maturity stage characterized by prolonged incremental performance growth and the crucial task of extending maintenance periodicity. Without clear insights, effective planning for servicing and overhauls becomes pure guesswork.

Constant pressure, leaving no time for long-term planning. This relentless pressure can severely hinder the vital decision-making required in the aging stage, where design limits are approaching, evidence of deterioration, and complex life extension investment decisions demand foresight and strategic thinking, often with the specter of minimal residual value looming large. It's like being constantly caught in a whirlwind, with no moment to step back and map a path forward. This is quite a deep issue. We won't dive into more, but keep in mind that it is also causing other areas.

Despite two decades of technological leaps. Therefore, the fundamental approaches to managing complex assets, such as rolling stock, haven't evolved simultaneously. This accurate information is derived from various arrays that showcase different advancements in the rail industry across each country.

Reluctance or inability to fully embrace modern solutions, this inertia could smooth out the slow performance growth of the so-called Infant Mortality stage, or prevent the escalating maintenance costs and uncertainty around remaining life. All that characterizes the aging stage of rail assets. Ultimately, this stagnation can lead to a painful end of life based on the cost of repairs or replacement at a certain stage.

A partnership approach to modern logistics and asset management

At Adexin, we understand that addressing the complexities of modern logistics and rolling stock management requires more than just off-the-shelf software. It demands a partnership. We position ourselves not as a product vendor but as a technology partner, a collaborator invested in your operational success.

We understand how hard it is to implement IT in live logistics processes. That's why we don't push systems. So, frankly, we create a custom rolling stock management system with you.

Our approach is rooted in a deep appreciation for the lifecycle of an asset, mirroring the main streams in effective asset management:

Understanding the need. Just as asset management begins with identifying the need for the asset, it also considers the company's requirements. We begin by thoroughly understanding your unique operational landscape and your rolling stock or fleet's specific challenges.

Strategic planning and preventing damaged products. We help you develop an asset management plan that goes beyond basic tracking and monitoring. This aligns with integrating with existing systems to provide actionable insights.

Ensuring accountability and safety. We support the accountability of select and line managers for all asset safety requirements. And at the same time, by building solutions that enhance oversight and compliance from the infant mortality stage to terminal decommissioning.

Tailored provision and maintenance. We focus on providing the asset, including its ongoing maintenance and repair, to suit its continuing needs, defining serviceability standards within our solutions. This means delivering working, tailored digital solutions that align with your specific maintenance periodicity and condition monitoring needs.

Optimizing operations. We help define and maintain operational standards for the asset's operation, ensuring your fleet runs at peak efficiency.

Streamlined disposal. When the time comes for disposal of the asset, when the need no longer exists, or it is no longer appropriate for the asset to be retained, our systems provide the data and insights for informed decisions, even for selective decommissioning of units or decommissioning for spares.

Integrated record keeping. Critical to all stages, our solutions ensure that inventory records are maintained and kept in the asset management system, linking seamlessly to existing standalone procedures, such as procurement of rolling stock and commissioning of rolling stock, relating to the separate asset lifecycle stages.

Need a custom asset tracking software solution?

We are happy to help you

Explore moreOur expertise extends to a range of specialized solutions. We offer specialized solutions, including a blockchain Digital Material Passport (DMP) app, eProcurement for supply chains, an AI-powered parking management system, and a blockchain-based shipping document platform. These demonstrate our tailored software for diverse logistical and operational challenges.

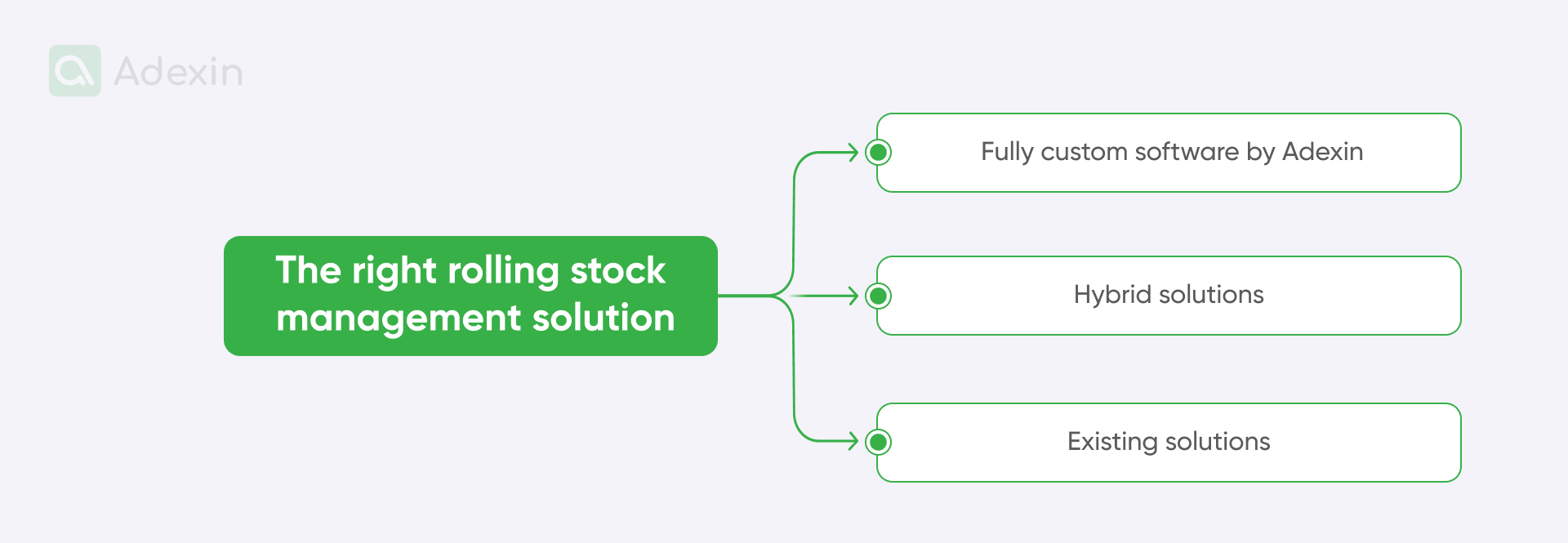

Choosing the right rolling stock management solution

Let's examine more closely how effectively managing the rolling stock is crucial for maintaining reliability, safety, and operational performance. The right solution can help you proactively address degradation, obsolescence, and environmental impacts.

We offer three clear solution paths to meet your specific needs. See below what is on the table:

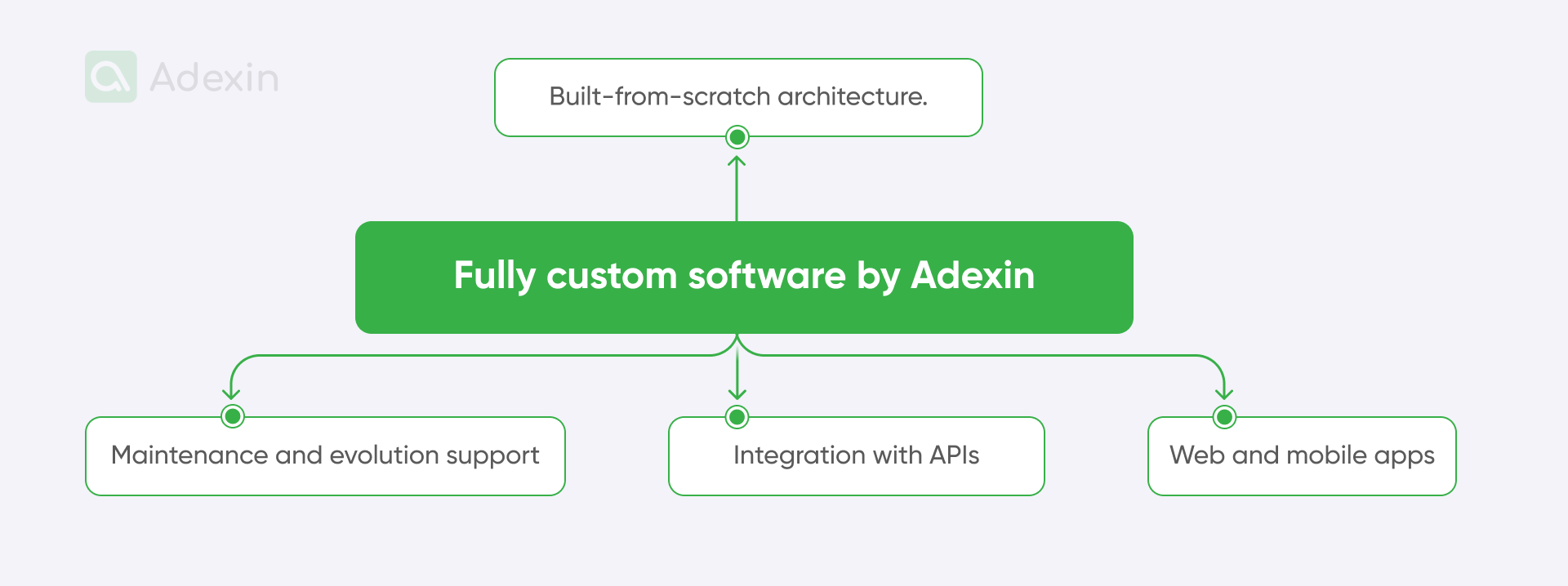

1. Fully custom software by Adexin

This approach is ideal for managing the entire asset life process, from understanding aging characteristics to feedback and review.

Built-from-scratch architecture. We design and develop custom solutions for your logistics, delivery chains, or partners. This allows for a system that perfectly mirrors your understanding of aging processes, decision points, mitigation strategies, and hard and soft landing approaches.

Web and mobile apps. Provide seamless access for your teams, whether they're in the office or the field, conducting condition assessments and defect identifications.

Integration with APIs. We ensure a smooth data flow by integrating the rolling stock management system with your existing systems, including carriers, customer relationship management (CRM) systems. This enables the centralization of vital data on rolling stock availability, historical performance, reliability, and maintenance, facilitating effective feedback and review processes.

Maintenance and evolution support. Our commitment extends beyond development, we provide ongoing support, updates, and evolutionary enhancements to ensure your software remains aligned with your operational needs and the latest technological advancements.

Pros and better control over stock levels:

Perfect fit. The software is designed precisely to your specifications, addressing every unique challenge and integrating seamlessly with your current workflows.

Competitive advantage. Gain a unique operational edge through highly optimized and efficient processes.

Scalability and flexibility. The system can be easily adapted and expanded as your business grows and your understanding of aging evolves.

Long-term value. A custom solution is an investment that provides significant returns through increased efficiency, reduced downtime, and improved decision-making.

Cons and stock discrepancies:

Higher upfront cost. Requires a greater initial investment compared to other options.

Longer development time. The most comprehensive option naturally requires the longest development period.

2. Hybrid solutions

This approach combines the benefits of existing solutions with the tailored functionality of custom development, offering a balanced solution for a rolling stock management system.

Tailored functionality with the latest technologies. We can develop custom-built modules like a specialized routing engine optimized for your specific maintenance schedules and operational constraints. This enables precise control over critical aspects of your aging management process, such as defect identification and mitigation strategies.

Optimized for your needs and prevents time-consuming actions. This blend ensures that core functions are handled by reliable, existing systems while unique challenges like specific defect analysis workflows or detailed historical performance tracking, necessary parts at the fingertips, predictive and preventive maintenance, or inventory control, are addressed with custom development.

Pros to determine:

Flexibility and customization. Enjoy the best of both worlds, standard features from existing tools, and tailored solutions designed to address your unique challenges.

Cost-effectiveness. More affordable than a fully custom solution while still offering significant customization.

Scalability. Enables growth by allowing the addition of new custom modules as your needs evolve, and less manual counting with better stock take and stock records.

Cons to determine:

Increased complexity. Managing integrations between off-the-shelf and custom components can be more intricate.

Longer development time. Requires more time than simply deploying existing solutions.

3. Existing solutions

This approach focuses on leveraging readily available, proven rolling stock management systems and other software solutions for various aspects of rolling stock management.

Fast integration. Many warehouse management systems (WMS) for necessary parts and stock take, transportation management systems (TMS) for routing and logistics, and business intelligence (BI) tools for data analysis and performance monitoring can be integrated relatively quickly.

Plug-and-play configuration. Such solutions often provide out-of-the-box functionalities that can be configured to fit existing workflows, enabling rapid deployment.

Pros to determine:

Speed of deployment gets up and running quickly with established systems.

Lower initial cost is often less expensive than custom development.

Proven reliability, these solutions are typically thoroughly tested and well-supported.

Cons to determine:

Limited customization may not fully meet unique operational requirements.

A redundant feature set leads to the possibility of paying for features you don't need.

Integration issues exist, although integration of multiple off-the-shelf systems is generally straightforward.

Why acting now unlocks operational excellence

You choose the flexibility, and we deliver solutions that adapt exactly to your operation. This isn’t theoretical, it is proven by real logistics leaders. Imagine a dispatcher viewing real-time fleet status on one unified screen, responding instantly to emerging issues. Managers don’t wait for delays they receive proactive alerts and resolve problems before downtime occurs. Executives rely on performance dashboards that reveal fleet health, stocktaking processes, and operational efficiency at a glance. With this structure in place, your company scales effortlessly, free from daily firefighting because intelligent, predictive rolling stock management systems and streamlined processes manage rolling stock for you.

This future is already here. Hupac, the Swiss intermodal freight operator, equipped over 1,000 wagons with smart sensors that transmit location, impact events, border crossings, and mileage every five minutes. Paired with Nexiot’s digital route-planning and traffic-management platform, this allowed automated rescheduling, delay prediction, and better resource allocation across Europe. In the United States, Union Pacific Railroad deployed an automated real-time dispatching system spanning its 50,000 km network in 23 states, using interconnected optimization modules to dynamically schedule trains, resolve conflicts, and improve network fluidity.

India offers equally striking cases. KONUX predictive and preventive maintenance is used by Deutsche Bahn to monitor thousands of rail switches, reducing failures and boosting punctuality. East Central Railway’s AI anomaly detection flags overheating axles, AC faults, and fire hazards before breakdowns occur. The machine vision-based inspection system automates inspections with AI/ML, speeding maintenance and enhancing safety.

Why risk delay? When you postpone adopting such intelligent systems, your processes stay siloed, and disjointed logistics spending can swell to 1.5-2 times the necessary amount. Disconnected tools lead to duplicated tasks, stock take errors, and waste. Worse, if you fall back on generic software that doesn’t suit your needs, you end up with a patchwork of systems that are costly, ineffective, and create more operational friction.

But companies that act now gain measurable advantages like reduced waste, heightened reliability, smoother operations, and strategic insight, empowering them to perform faster, leaner, and smarter every single day. Bring the future forward and transform how you manage rolling stock.

Are you in search of a reliable tech partner?

Adexin can help with advanced logistics solutions

Contact usFinal takeaway

Effective rolling stock management is no longer about simply keeping trains moving, it’s about integrating intelligent, tailored systems that unify data, streamline operations, and anticipate issues before they arise. Companies that act now, choosing the right mix of custom, hybrid, or existing solutions, can unlock long-term efficiency, cost savings, and strategic agility, turning a complex challenge into a sustainable competitive advantage.

Ready to optimize your rolling stock management and mitigate the impacts of aging? Contact us today to discuss which solution path is right for you!